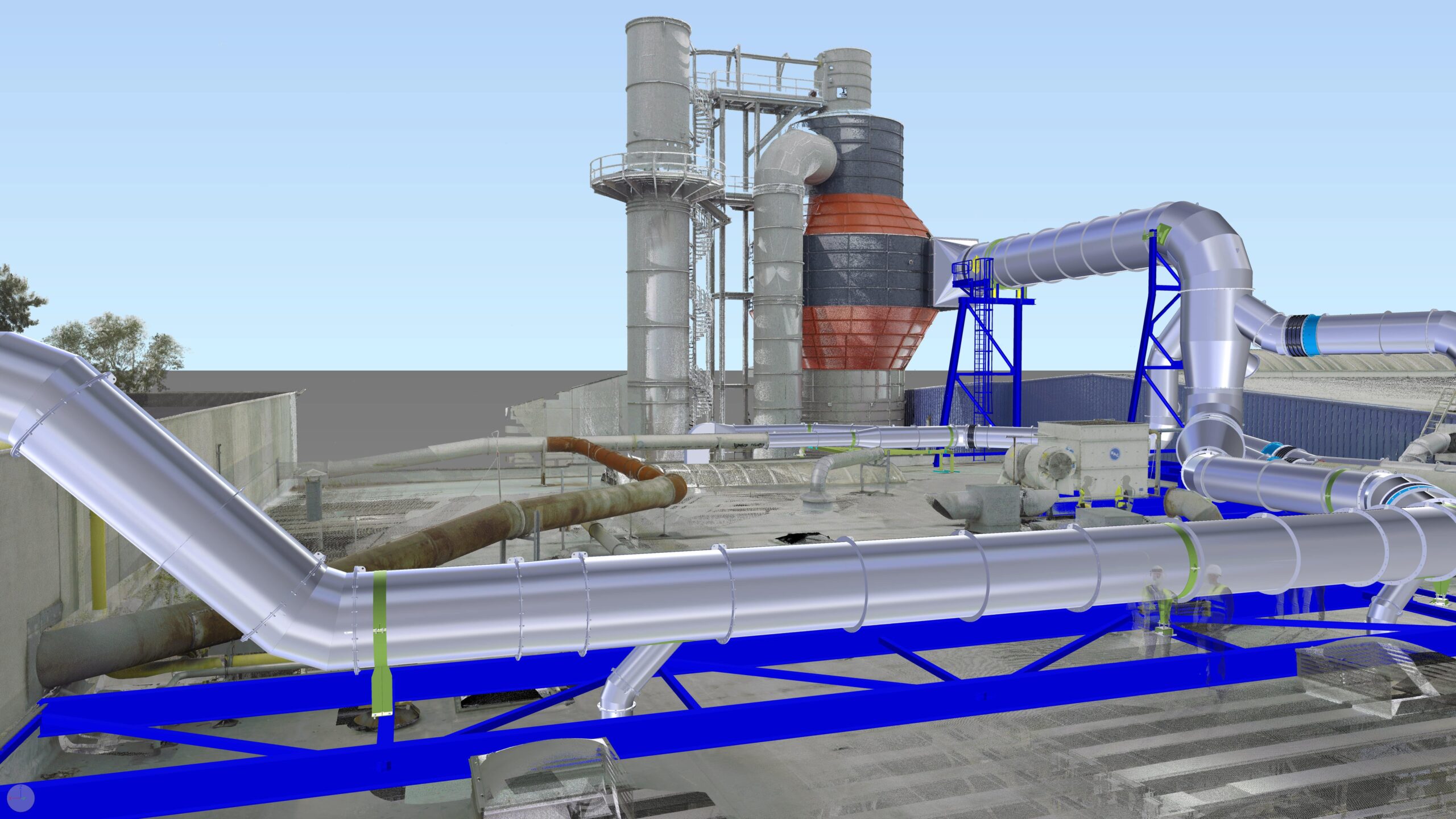

REAZN Belgium, specialist in zinc recycling, replaces its three filter units and expands its capacity with one gigantic filter of about 33 metres high and 11 metres in diameter. Lybover METAL contributes by providing all ducting, structures and a piperack. On the same site, Lybover BULK installed a cleverly designed big bag filling station with four filling units.

Strength calculation, stress calculation of the piping, complex drawing work, 3D scanning, … For this assignment, Lybover pulled out all the stops. We brought different internal expertises together and approached the right suppliers. That made Lybover METAL the best partner to bring this project to a successful end. The colleagues of Lybover BULK delivered an important addition to the filter: a big bag filling station to collect and dispose of the filter dust.

Construction in two phases

REAZN specialises in the recovery, recycling and re-industrialisation of zinc alloys. The company uses melting furnaces for this purpose. During combustion, dust and gases are released which are extracted to a filter via a pipe network. REAZN had three of these on its site. To comply with stricter environmental regulations and to be able to expand in the future, the three existing dedusting filters were taken out of service and replaced by one filter unit with a larger capacity.

“Lybover provided suitable ducting with a diameter of 2.5 metres. We did that in two phases”, explains Wout Decoutere, Sales Engineer Projects at Lybover METAL. “REAZN wanted to be able to commission part of the installation already so that the filter could be partially started up and tested. So, in the first phase, we installed the largest pipe and other connections needed for this. In the second phase, the slightly smaller connections followed. “

Challenges and solutions

“In this project, we had to take many factors into account,” Wout continues. “The strength calculation was a complex task. Due to the great height of the structure, we first had to consider the wind load. The stress resistance of the pipes was also extremely important. Heat, wind load, pushing and pulling forces all have their influence. For example, the pipes discharge hot gases that cool down during transport. The finishing had to take this into account. A perfect seal was also needed. Another factor was the length of the pipes. They were not allowed to bend, and so on. “

“Another difficulty was to be able to place the new pipework on top of the structure of the existing building. The filter is very high and sticks out above the roof. The roof was not designed to accommodate the new pipework. We met with the architect several times and proposed several structures to support and reinforce the roof. Thus, we built the two main structures that support the large pipe. We also made about six different support structures on which the slightly smaller tubes run, just above the roof. “

The added value of 3D scanning

“The 3D scanning was also a great added value here,” confirms Wout. “Because we had worked for REAZN before, we already knew the site quite well. The older scans came in handy because some of the existing pipes had to be reused. We took out a section, added new sections and were then able to connect the existing pipes to the new filter. “

In order to get the full picture for the new installation, only a small additional section had to be scanned. The great advantage of 3D scanning is that you immediately have the exact existing situation to draw on. This also ensures smooth production and assembly.

Big bag filling station by Lybover BULK

For Lybover, the work did not stop with the installation of the huge ducting. Lybover BULK was also active on the REAZN site. They installed a cleverly designed big bag filling station. The filter dust from the extraction installation is collected there in big bags by means of screw conveyors. For this installation, we worked together with our regular German partner EMDE Automation, specialist in big bag handling systems and dosing devices for bulk materials.

In total, we installed four filling units at REAZN. They offer sufficient capacity so that they do not have to be changed constantly. In addition to sufficient storage capacity, the design also took into account smooth and safe operation. For example, the four big bag hooks on the filling units are pneumatic so that they fold away at the press of a button. This allows the filled big bag to be removed quickly and efficiently. The units were pre-assembled to reduce assembly time on site.

An installation for the future

Today, REAZN is ready for the future with its huge installation. The installation flawlessly meets the stricter emission standards of 5 mg/m³ and even goes a step further with an emission level below 1 mg/m³. The fact that Lybover was able to collaborate on such an ambitious installation also meant that we could once again expand our engineering horizons.