GS Yuasa Battery Europe, the largest supplier of lead-acid and lithium-ion batteries in Europe for more than 30 years, finds a partner in Lybover AIR to design dedusting installations for its production plant in Wales. The successful dedusting solution for a brand new cutting and brushing machine convinced GS Yuasa Battery Manufacturing UK to work with Lybover AIR for a second order as well. This time it involved a dedusting system for a battery production line. How does Lybover AIR win over GS Yuasa? Expertise, thinking along and being flexible are the keys to success, according to Paul Barrick, Managing Director of Luksal (Lybover AIR UK).

Convincing the customer of our expertise and commitment led to a successful partnership between Lybover AIR and GS Yuasa Battery Manufacturing UK. This allowed us to optimise an existing design and for a second, larger project, use 3D scanning to make a difference.

Our unique approach to dedusting a new cutting and brushing machine

The new, state-of-the-art cutting and brushing machine prepares lead plates for battery enclosures. Lybover’s brief was to improve the extraction of lead dust to meet stringent emission standards and create a healthy working environment for production workers.

“We soon came to the conclusion that the design of the cutting and brushing machine presented us with challenges. For example, the emission points were not quite correctly designed. So we explained very honestly and transparently why the exhaust hood was not designed correctly by the manufacturer of the machine. We invested quite a lot of time and energy in it”, explains Paul Barrick.

According to Barrick, this approach sets Lybover AIR apart from its competitors. “Anyone can sell and install a dedusting filter, but we go further. We think along and the customer knows where they stand. We don’t just say we have expertise, we show it, without imposing our solutions. GS Yuasa greatly appreciated that.”

The result after the extra mile

The experts of Lybover AIR showed how to improve the product design, working closely with GS Yuasa. This laid the foundation for great mutual trust. And the result is impressive: the dedusting system is efficient and much quieter than previously envisaged – so a lot healthier and more pleasant for the production workers.

Paul Barrick: “We don’t just sell dedusting installations, we do everything we can to build a relationship with our customers. GS Yuasa understood that there were challenges with their initial design and that we were trying to help them. They took our advice to heart and gave us the confidence to start a new project.”

The added value of 3D scanning in the battery cell production line

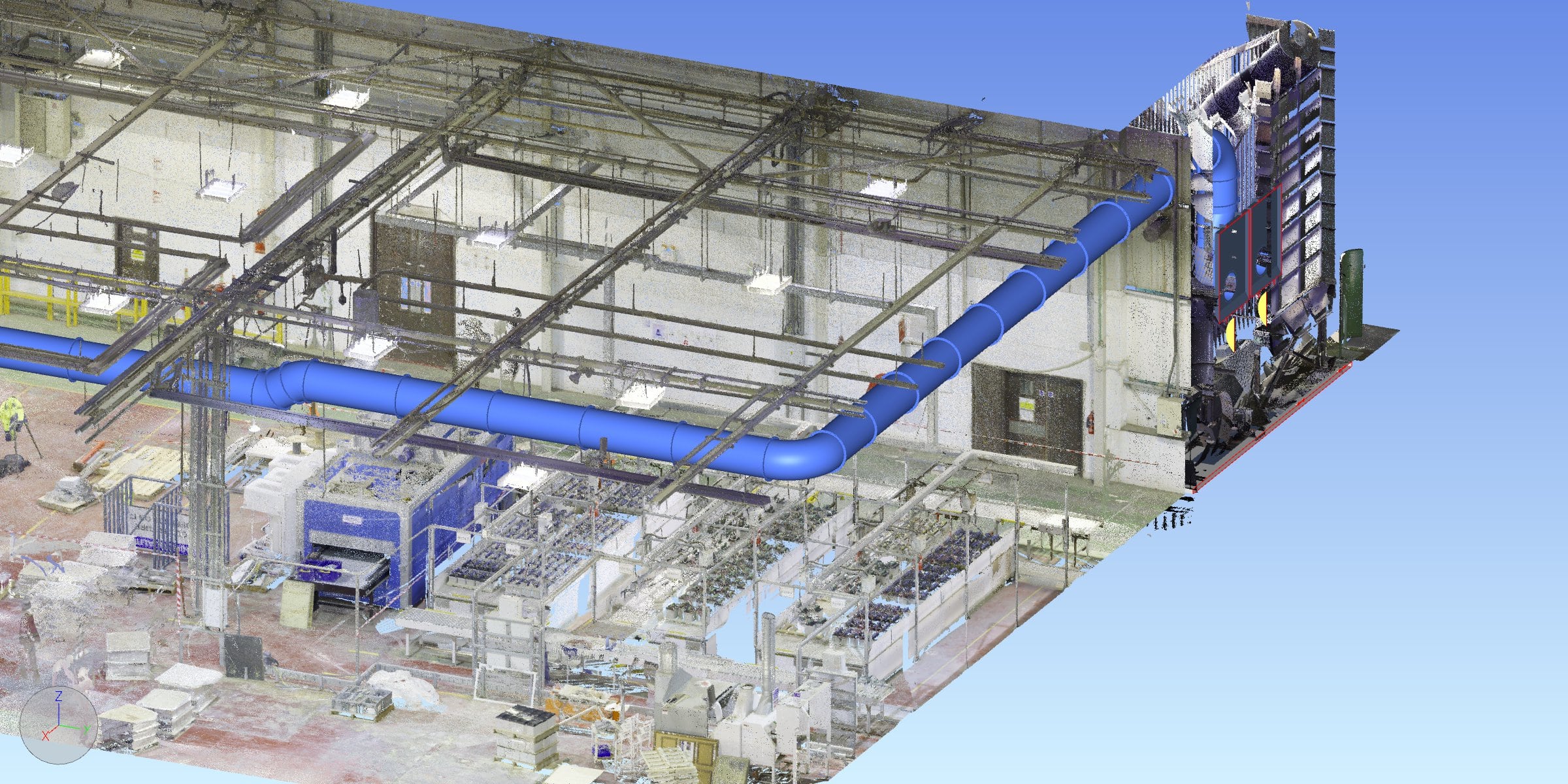

Soon Lybover AIR was invited to discuss a second project: a dedusting system for a battery cell production line. The next logical step in the production process, because after the cutting and brushing machine, this is where the lead plates end up. The challenge? Fitting the system neatly into the plant, taking into account existing equipment, utility lines and other obstacles. The solution? 3D scanning.

Paul Barrick: “The 3D scanning allowed us to visualise and properly explain the challenges of the installation. Moreover, GS Yuasa can use the renders in the future. That makes the 3D scanning an added value for us as well as for the customer.” 3D scanning is not the only technology GS Yuasa is taking advantage of. Lybover AIR engineers can monitor installations remotely. How does it work? When the customer calls us with a problem, we log in and find out exactly where the customer is stuck. This is much quicker than sending a technician on site.

Paul Barrick: “This was not the most complex project for us. But it did require a lot of flexibility. GS Yuasa appreciates that, as they have since asked us to look at other systems as well. To be continued.”