The Westeria material distribution systems ensure perfect material spreading for all kind of detection and separation processes.

DiscSpreader®

Optimal material distribution is essential for many sorting processes, whether NIR, ballistic sorting or air separation. Only if the entire belt width is really evenly loaded with material, the sorting machines are used profitably.

- 360° material feeding

- Up to 7 m shorter system than other distribution systems

- Precise alignment of the distribution discs

Low maintenance

The cleaning effort is extremely low thanks to the short contact between material and machine. The solid discs can be used for even the toughest applications and are easy to replace. The motors are completely protected from material and are also easy to reach.

Simple and quickly available

Thanks to the standardized design and upstream assemblies, the distribution system is ready for shipment extremely quickly and can be assembled locally without expertise.

Low space requirement

Since the DiscSpreader is simply integrated onto the conveyor belt or directly into the sorting machine, you save the space of a separate machine.

Feeding from all sides

Thanks to the various feed hoppers, the material can be fed from all sides. This allows complete freedom in plant design.

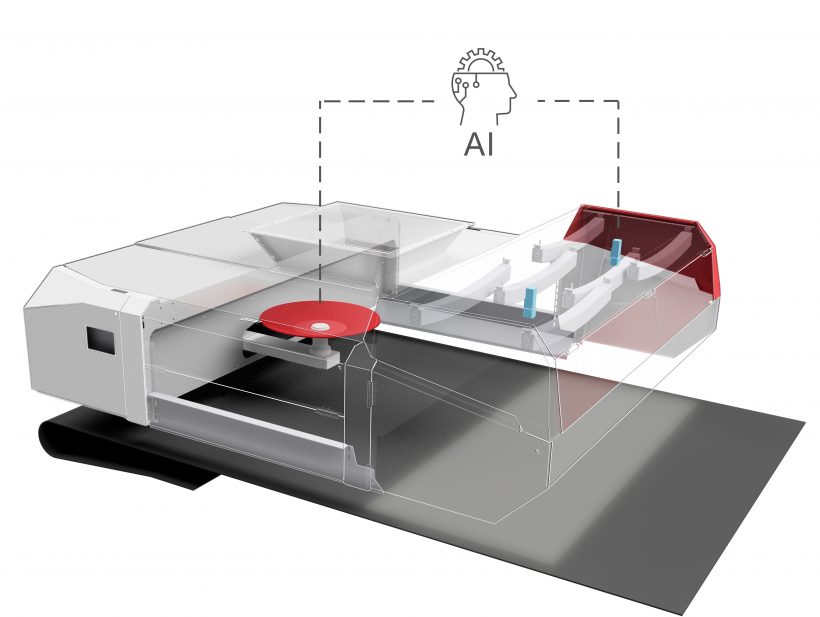

DiscSpreader® automove

Our DiscSpreader are known for their perfect material distribution of glass, wood, compost, scrap, slag, waste or any other type of bulk material.

Together with leading AI developers from the Technical University of Cologne, we have developed a solution that automatically aligns the discs with the help of artificial intelligence. Cameras above the conveyor belt permanently monitor how the material is distributed. There is no longer any need for staff to re-align the distribution disc if the distribution quality is no longer optimal. The self-learning algorithm permanently collects new data and can thus adjust to any change in the material flow at lightning speed. The patented system is mounted directly on the accelerator belt and thus ensures maximum efficiency of subsequent sorting units.

- Permanent monitoring of the distribution quality

- AI controlled disc alignment

- Highest effectiveness for subsequent separation