In the valorisation hall of waste to product company Renewi in Roeselare, organic waste materials are mixed in bunkers using an excavator. The same hall also houses a shredding installation where waste is mechanically reduced, with or without the addition of absorbents. The manipulation of these waste materials and absorbents can cause emissions of odour and dust. In order to eliminate any potential environmental impact , Renewi was looking for a tailor-made solution. Together with partner Desotec, the experts of Lybover AIR realised this sustainable project from concept to assembly.

To avoid emissions, it is first of all necessary to put the valorisation hall in underpressure. Lybover AIR identified 4 extraction points distributed over the width of the hall at the height of the roof. The suspended dust that previously remained in the hall is extracted at these extraction points.

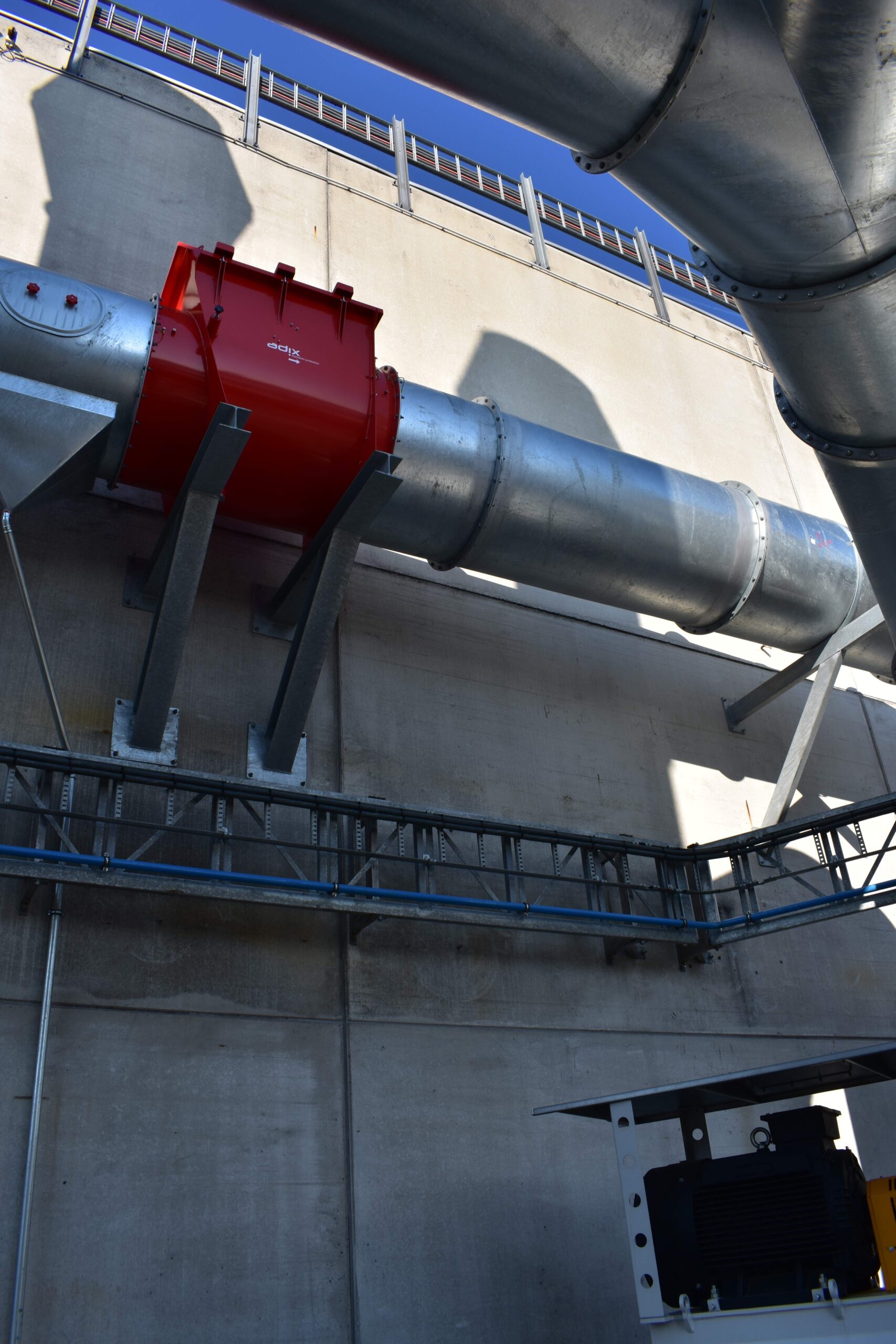

Based on the emission measurements and a comprehensive examination of the actual situation, our engineers opted for a PT filter with constructive ATEX protection. A plate filter from partner Keller turned out to be the best solution here as it concerned very fine dust particles. The PT filter guarantees an emission of <0.5mg/Nm³. The dirty air is drawn in through the top and then flows downwards over the filter elements. A self-cleaning filter is essential for continuous operation of the extraction. The plate filter is cleaned with compressed air pulses so that it can maintain its flow rate continuously. Since the dust extracted is potentially explosive, the appropriate ATEX components were also used so that no explosion can be created in the filter. Due to the high filter efficiency, the activated carbon filter is hardly burdened with dust particles. The activated carbon filter eliminates odour emissions in a final step.

Special attention was also paid to the pipework. Because of the changing composition of the extracted dust particles, the pipework was provided with hot-dip galvanised sheet material. The complete project preparation, assembly work and commissioning was carried out by Lybover AIR.